Fill all information details to consult with us to get services from us

In the intricate network that delivers electricity to our homes and businesses, every component plays a crucial role. Among these, Medium voltage support insulators stand as unsung heroes, ensuring the safe and reliable transmission of power. At Radiant Enterprises, we understand the critical nature of these components, and as a leading Medium voltage support insulator exporter in India and Medium voltage support insulators manufacturers in India, we are committed to providing high-quality products that meet the demanding needs of modern power systems. This blog post will delve into why these insulators are so essential for reliable power distribution.

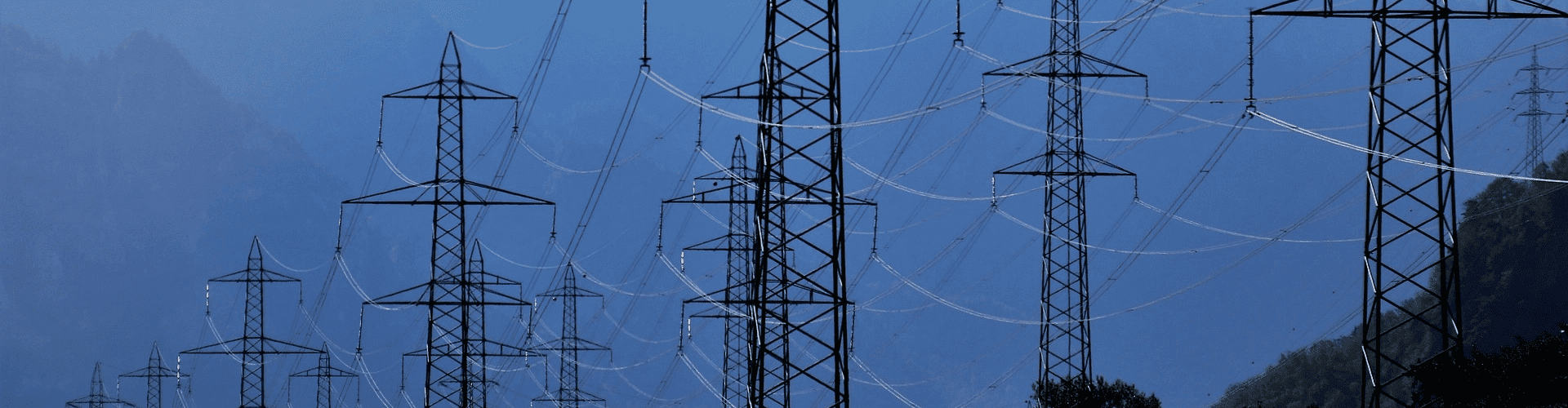

Medium voltage power lines, typically ranging from 1kV to 69kV, form the backbone of our electricity distribution networks. These lines carry power from substations to local distribution points, ultimately feeding homes and industries. To ensure the safe and efficient transmission of this power, conductors must be securely mounted and electrically isolated from supporting structures like poles and towers.

These insulators are designed to provide mechanical support for conductors while simultaneously offering electrical insulation. They prevent current leakage and short circuits, which can lead to power outages, equipment damage, and even safety hazards. The reliability of the entire power distribution network hinges on the performance of these seemingly simple components.

Electrical Insulation: The primary function of a Medium Voltage Support Insulator is to provide a high level of electrical resistance, preventing current from flowing through the supporting structure. This ensures that the electrical energy is channelled correctly along the conductors.

Mechanical Support: Power lines are subject to various mechanical stresses, including the weight of the conductors, wind pressure, ice loading, and tension forces. The insulator must be robust enough to withstand these forces without breaking or deforming, thus maintaining the integrity of the power line.

Environmental Withstand: Outdoor insulators are exposed to harsh environmental conditions such as rain, sunlight, temperature variations, pollution, and salt spray. They must be designed to resist degradation and maintain their insulating properties over time.

Preventing Flashovers: A flashover occurs when an electrical discharge jumps across the surface of the insulator, bypassing the intended current path. Insulators are designed with specific shapes and materials to minimise the risk of flashovers, even under adverse weather conditions.

Several types of Medium voltage support insulators are available, each suited to specific applications and environmental conditions.

Pin-type Insulators: These are typically used for lower medium voltages and are mounted on pins attached to the supporting structure.

Suspension Insulators: Used for higher medium voltages, these consist of a series of interconnected discs that hang from the cross-arm. This design allows for greater flexibility and higher voltage ratings.

Post Insulators: These are rigid insulators that provide both mechanical support and electrical insulation. They are often used in substations and switchyards.

Composite Insulators: Made from non-ceramic materials like fibreglass reinforced polymer, these offer advantages such as lighter weight, high mechanical strength, and resistance to pollution. Epoxy insulators fall under this category and are known for their excellent electrical and mechanical properties.

Selecting the appropriate Medium voltage support insulator is crucial for ensuring the reliability and safety of the power system.

Voltage Level: The operating voltage of the power line dictates the required insulation level of the insulator.

Mechanical Loading: The insulator must be able to withstand the mechanical stresses imposed by the conductors and environmental factors.

Environmental Conditions: The presence of pollution, humidity, and salt spray can affect the performance of the insulator.

Material Properties: The material of the insulator, such as porcelain, glass, or polymer, influences its electrical and mechanical characteristics.

Cost and Maintenance: The initial cost of the insulator and its long-term maintenance requirements should be taken into account.

At Radiant Enterprises, we specialise in the design, manufacture, and export of high-quality Medium voltage support insulators. As a leading Medium voltage support insulators manufacturers in India and Medium voltage support insulator exporter in India, we have a deep understanding of the challenges faced by power utilities and offer a comprehensive range of solutions to meet their needs.

Medium voltage support insulators are indispensable components of modern power distribution systems. They ensure the safe and reliable transmission of electricity by providing electrical insulation and mechanical support to conductors. Choosing the right insulator is critical for preventing power outages, equipment damage, and safety hazards. Radiant Enterprises, a leading Medium voltage support insulator exporter in India and Medium voltage support insulators manufacturers in India, is dedicated to providing high-quality insulators that meet the demanding requirements of today's power networks. Contact us today to learn more about our products and how we can help you build a more reliable and efficient power system.